The quality of a product lies in the process of production, not just the results of testing.

Winday is the quality leader in the capacitor industry.

This conclusion is continuously confirmed by the reviews of our top customers and the quality and service rewards we receive.

Winday factory passed ISO9001:2015 and IATF16949:2016

This proves that the quality assurance team, equipment and monitoring in our factory are in line with internationally accepted standards.

All Wedie products are manufactured in accordance with IEC specifications.

Winday Quality System

Quality policy based on corporate objectives and commitment to total quality.

1. Winday's quality policy

The quality of our products and services is an important part of our strategy, and our primary goal is customer satisfaction.

The ultimate goal of quality management system is to produce perfect and high-level products, and always keep in line with the interests of users.

Our quality management system always embodies the most stringent international standards.

2. Quality management system

IATF16949:2016 quality management system is applied to the whole company in order to achieve the Winday quality policy.

These effects include:

* The development of products and processes follows the rules of product quality advance planning.

Quality measures, such as potential failure modes and audio-visual analysis, experimental design, and statistical process control, reduce risk,

Ensure continuous improvement and regular internal audit and quality review.

3. The certification

The quality management system of Weidi is based on ISO9001:2015 and IATF16949:2016 certification, which includes Weidi factory and sales department.

The certificate is posted on the Winday website.

4. Quality plan

Project-oriented improvement programs, guided by professional teams, establish the strategic goal of pursuing zero defects.

5. Quality of delivery

"Quality of delivery" means compliance with delivery times and promised product consistency.

6. Failure criteria

If a feature of the product does not conform to the specification data sheet or agreed delivery specification, then the component is defective.

7. Traceability

At all stages of production, each batch is supported by documentation that records materials used, manufacturing and testing steps until completion. This will ensure traceability from batch to batch.

8. Final inspection/outgoing inspection

The final inspection mainly uses fully automated sorting test equipment to verify the main performance of the products batch by batch, and the outgoing inspection helps to ensure that the products meet the specifications.

These include:

* Test the main parameters

* Identification and appearance inspection

* Outgoing inspection report

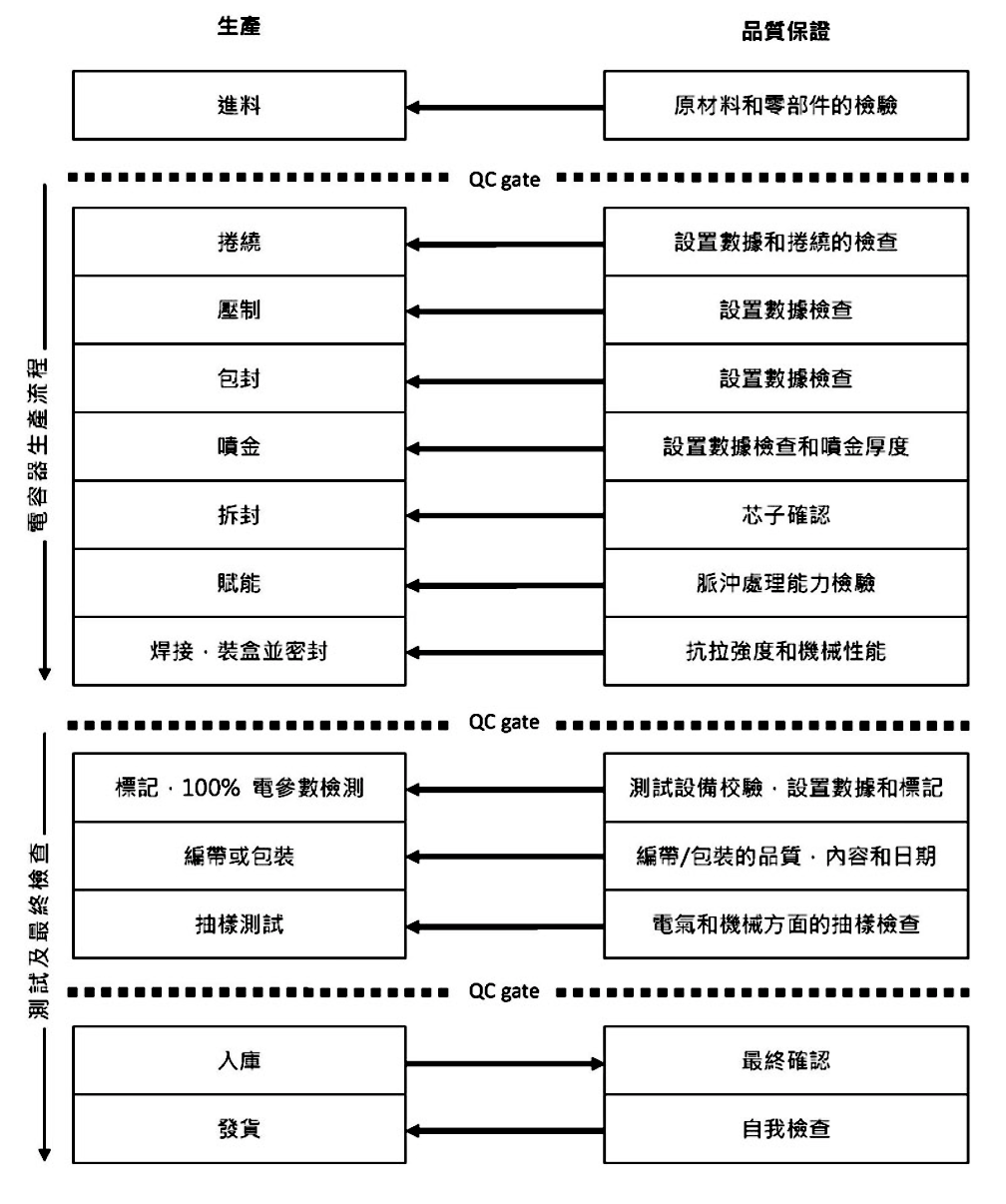

9. Manufacturing quality assurance procedure flow chart

10. Quality process flow chart